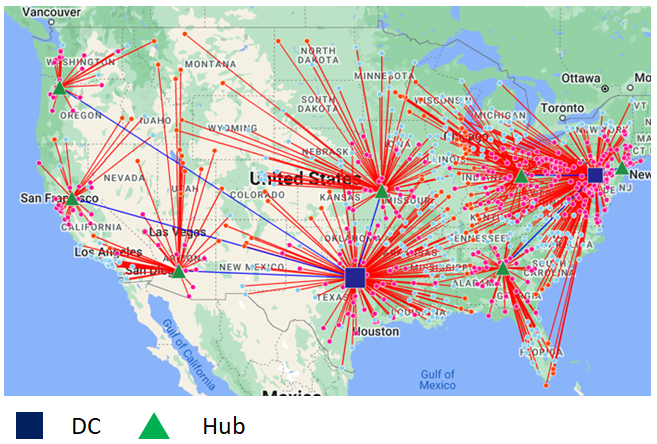

Ready to Get started?

Optimize your supply chain with Optiflow’s powerful tools and features. Our user-friendly platform offers advanced optimization capabilities and what-if analysis for data-driven decision-making. Start unlocking your supply chain’s full potential today with Optiflow